Delivery time: 3 - 5 working days

do88 performance intercooler, designed for an easy installation fit in your BMW M2 / M3 / M4 F8X

The S55 turbo engine that powers the BMW M2C / M3 / M4 F8X uses a top mounted water cooled intercooler instead of a "normal" air cooled intercooler. This OE intercooler has a tube&fin core with clamped plastic end tanks. This design has its drawbacks as it is prone to cracking and starting to leak coolant into the engine or losing boost pressure from the tank seals.

Our mission in developing this new performance intercooler was to eliminate the weaknesses of the OE intercooler and of course provide a huge increase in performance. In all the testing we have done during the development of our entire BMW F8X M2C/M3/M4 range, we clearly see how peak performance is directly related to IAT (Intake Air Temperature).

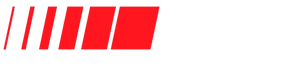

To get an accurate 3D model of the space available for designing our intercooler, we performed a detailed 3D scan of our M3 Competition engine bay. In our Solidworks CAD software, we tried out several design concepts for our intercooler using the 3D scan generated model.

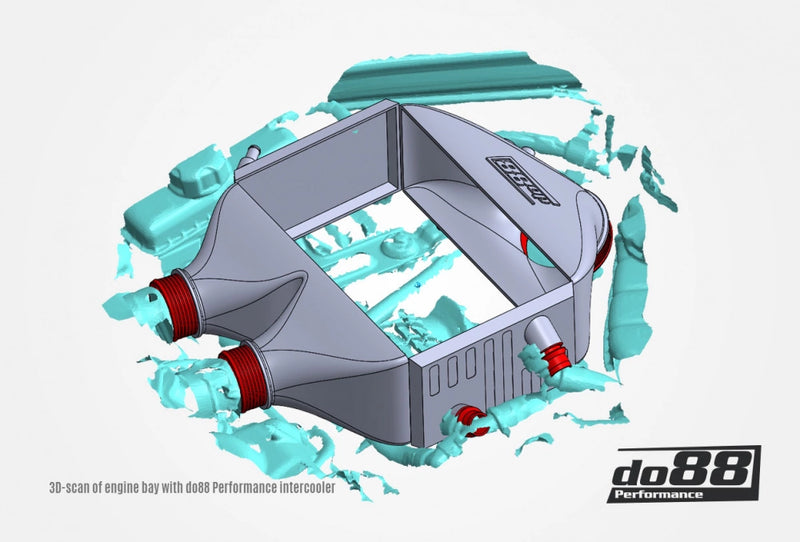

The final design concept was decided after several CFD simulations in our Solidworks Flow Simulation software. In this software we can simulate the airflow and measure the pressure drop and air distribution across the mesh. We decided not to include internal air ducts as several of our simulations showed that they did more harm than good. The airflow is perfectly distributed across the mesh with our tank design without internal air ducts as many claim it is good. But in many cases these cause turbulence and disturbances in the airflow.

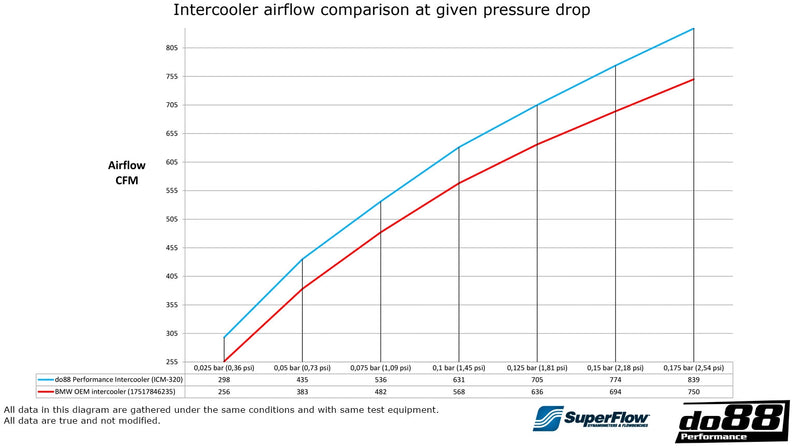

Our final design resulted in a bar-and-plate mesh with TIG welded cast aluminum tanks. This provides peace of mind for any high pressure tune. We managed to utilize a massive mesh that is 85% larger than OEM and reduce the boost pressure drop (16% lower) and keep the installation without modifications. Reducing the boost pressure drop across the intercooler has several benefits such as the turbos having to work less to reach target boost / lower temperature / improved throttle response. We have the equipment to calculate the pressure drop in our CFD calculation software and also do real world testing on our Superflow SF-1020 flow dyno. On the water-coolant side, we switched to a dual flow structure that allows the coolant to flow across the mesh twice before leaving the intercooler rather than the OE single flow structure.

We use a high density offset cooling fin on both the air and water cooling sides. Multiple tests were performed to find the optimal balance between the air and water fins to achieve the maximum heat transfer. This gives our intercooler a huge increase in active cooling surface area compared to the OE.

Of course, this is a do88 performance product, so we have done thorough, rigorous and continuous testing to ensure the best performance when developing this product. No compromise was made.

All of this hard work results in a product that, in one way or another, will truly improve the performance of your vehicle, whether it's a stock car or a heavily modified monster! On the track, on the street, on the strip, this intercooler will be your faithful companion!

Significant advantages with the do88 Performance intercooler (comparative figures to stock):

- Peak power increase of 13 HP! Measured on the car with BootMod3 Stage 1 tuning.

- Highest power increase in the mid speed range of 25 HP!

- Highest torque increase of 52 Nm!

- Larger net volume: 5657cm3 (3052cm3), 85% larger!

- Airflow at 0.025bar/0.36psi pressure drop: 298 CFM (256 CFM), 16% higher!

- Lower post-intercooler temperature under the same conditions: 39°C (48°C), 9°C lower!*

- Fits all cars in the list below!

* Measured at 240 km/h during full throttle acceleration from 0-240 km/h on a runway. Both tests were conducted on the same day under the same conditions.

Delivery time: 3 - 5 working days

do88 performance intercooler, designed for an easy installation fit in your BMW M2 / M3 / M4 F8X

The S55 turbo engine that powers the BMW M2C / M3 / M4 F8X uses a top mounted water cooled intercooler instead of a "normal" air cooled intercooler. This OE intercooler has a tube&fin core with clamped plastic end tanks. This design has its drawbacks as it is prone to cracking and starting to leak coolant into the engine or losing boost pressure from the tank seals.

Our mission in developing this new performance intercooler was to eliminate the weaknesses of the OE intercooler and of course provide a huge increase in performance. In all the testing we have done during the development of our entire BMW F8X M2C/M3/M4 range, we clearly see how peak performance is directly related to IAT (Intake Air Temperature).

To get an accurate 3D model of the space available for designing our intercooler, we performed a detailed 3D scan of our M3 Competition engine bay. In our Solidworks CAD software, we tried out several design concepts for our intercooler using the 3D scan generated model.

The final design concept was decided after several CFD simulations in our Solidworks Flow Simulation software. In this software we can simulate the airflow and measure the pressure drop and air distribution across the mesh. We decided not to include internal air ducts as several of our simulations showed that they did more harm than good. The airflow is perfectly distributed across the mesh with our tank design without internal air ducts as many claim it is good. But in many cases these cause turbulence and disturbances in the airflow.

Our final design resulted in a bar-and-plate mesh with TIG welded cast aluminum tanks. This provides peace of mind for any high pressure tune. We managed to utilize a massive mesh that is 85% larger than OEM and reduce the boost pressure drop (16% lower) and keep the installation without modifications. Reducing the boost pressure drop across the intercooler has several benefits such as the turbos having to work less to reach target boost / lower temperature / improved throttle response. We have the equipment to calculate the pressure drop in our CFD calculation software and also do real world testing on our Superflow SF-1020 flow dyno. On the water-coolant side, we switched to a dual flow structure that allows the coolant to flow across the mesh twice before leaving the intercooler rather than the OE single flow structure.

We use a high density offset cooling fin on both the air and water cooling sides. Multiple tests were performed to find the optimal balance between the air and water fins to achieve the maximum heat transfer. This gives our intercooler a huge increase in active cooling surface area compared to the OE.

Of course, this is a do88 performance product, so we have done thorough, rigorous and continuous testing to ensure the best performance when developing this product. No compromise was made.

All of this hard work results in a product that, in one way or another, will truly improve the performance of your vehicle, whether it's a stock car or a heavily modified monster! On the track, on the street, on the strip, this intercooler will be your faithful companion!

Significant advantages with the do88 Performance intercooler (comparative figures to stock):

- Peak power increase of 13 HP! Measured on the car with BootMod3 Stage 1 tuning.

- Highest power increase in the mid speed range of 25 HP!

- Highest torque increase of 52 Nm!

- Larger net volume: 5657cm3 (3052cm3), 85% larger!

- Airflow at 0.025bar/0.36psi pressure drop: 298 CFM (256 CFM), 16% higher!

- Lower post-intercooler temperature under the same conditions: 39°C (48°C), 9°C lower!*

- Fits all cars in the list below!

* Measured at 240 km/h during full throttle acceleration from 0-240 km/h on a runway. Both tests were conducted on the same day under the same conditions.